Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

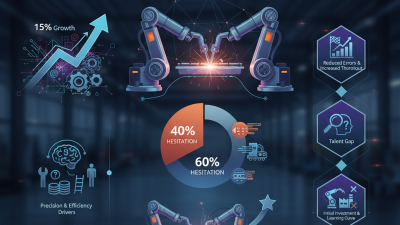

The landscape of manufacturing is evolving rapidly. Robotic welding solutions are becoming integral for efficient processes. According to the International Federation of Robotics, the global market for industrial robots is projected to grow by 10% annually, highlighting the industry's shift towards automation.

Experts like Dr. Emily Chen, a leading robotics engineer, emphasize the importance of such systems. She states, “Robotic welding solutions not only enhance productivity but also improve consistency in welding quality.” This is critical, as manufacturers face increasing pressure to meet high-quality standards and reduce production times. However, the implementation of robotic systems poses challenges, including the initial costs and the need for skilled operators.

Moreover, many companies still grapple with integrating these technologies effectively. Some firms report struggling to maintain their traditional workflows alongside automation. As industries push towards innovation, reflecting on these hurdles is crucial. Continuous improvement in robotic welding solutions could redefine manufacturing's future. Yet, we must address these imperfections to maximize their potential.

In 2026, robotic welding technology is witnessing significant advancements. Robots now possess greater precision and speed than ever before. Many manufacturers are investing heavily in automation. This shift aims to enhance productivity and reduce operational costs.

Welding robots can perform complex tasks with minimal supervision. However, the integration of these systems is not without challenges. Training staff to operate and maintain robots requires time and resources. Additionally, the initial investment can be a barrier for smaller companies. Implementing automation does not guarantee immediate success. Companies must adapt their workflows to fully utilize these technologies.

Another concern is the safety of robotic systems. Although robots reduce human error, they pose risks if not properly programmed. It is essential to have robust safety measures in place. Regular assessments and updates to the systems are crucial for long-term efficiency. As the industry evolves, manufacturers will need to remain vigilant. Embracing change while acknowledging its complexities will define the future of robotic welding.

Robotic welding solutions are transforming manufacturing processes. Many companies are adopting them to improve efficiency. According to recent industry reports, over 35% of manufacturers use robotic welding to increase production rates.

Key features of top robotic welding solutions include advanced sensors. These sensors enhance precision and adapt to different materials. Real-time monitoring is also crucial. It allows manufacturers to make quick adjustments. Reports show that real-time data analysis can reduce defects by up to 30%.

However, there are challenges to consider. Training employees on these complex systems can be time-consuming. Many companies report initial setbacks in productivity. Moreover, maintenance of robotic systems is often overlooked. Regular upkeep is essential; neglect can lead to costly breakdowns. The balance between automation and human oversight is a constant discussion in factories.

Robotic welding is transforming manufacturing efficiency. These advanced systems enhance precision and speed. This leads to reduced production times and higher output rates. Manufacturers can meet demand more effectively. Robots work tirelessly, minimizing human error and improving weld quality. The risk of defects decreases significantly, resulting in better products.

Tips for implementing robotic welding include clear planning. Assess your production needs thoroughly before investing. Understand how automation can fit into your existing processes. It's crucial to ensure the technology aligns with your goals. Additionally, provide proper training. Staff needs to adapt to new technology. This step is often overlooked but is essential for smooth integration.

While robotic welding offers many benefits, not everything is perfect. Initial costs can be high, which might deter some manufacturers. Maintenance is another consideration. Regular checks and updates are necessary to keep systems running smoothly. Evaluate your long-term needs and weigh them against these challenges. This reflection can help you make informed decisions about your manufacturing processes.

The landscape of robotic welding systems is evolving rapidly, driven by advancements in automation and technology. According to a recent industry report, the global market for robotic welding is expected to reach $6.82 billion by 2026, reflecting a compound annual growth rate of 9.5%. Manufacturers are seeking efficient solutions to enhance productivity, reduce labor costs, and improve safety. Among various options, systems vary in precision, ease of programming, and adaptability to different materials.

A comparative analysis highlights noteworthy differences among leading robotic welding systems. For instance, some systems offer advanced vision capabilities that improve alignment and reduce rework. However, these high-end systems often come with a steep learning curve. A report from a leading research firm indicates that companies investing in training for their operators see a 30% increase in welding efficiency. On the flip side, those neglecting operator education may find their return on investment diminish.

Flexibility is another crucial factor. Some robotic welding systems excel in high-mix, low-volume production, while others are tailored for mass production. Choosing the right system requires careful consideration of manufacturing needs. Factors like workspace constraints and material compatibility can complicate decisions. An underestimated risk, often overlooked, lies in maintenance costs over time, especially for complex systems. These aspects necessitate ongoing assessment and optimization to ensure sustained productivity and operational success.

| Feature | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Payload Capacity | 20 kg | 25 kg | 30 kg |

| Welding Speed (m/min) | 1.5 | 1.8 | 2.0 |

| Programming Ease | Moderate | Easy | Moderate |

| Precision (mm) | 0.1 | 0.08 | 0.05 |

| Software Compatibility | Yes | Yes | No |

| Price ($) | 15,000 | 18,000 | 20,000 |

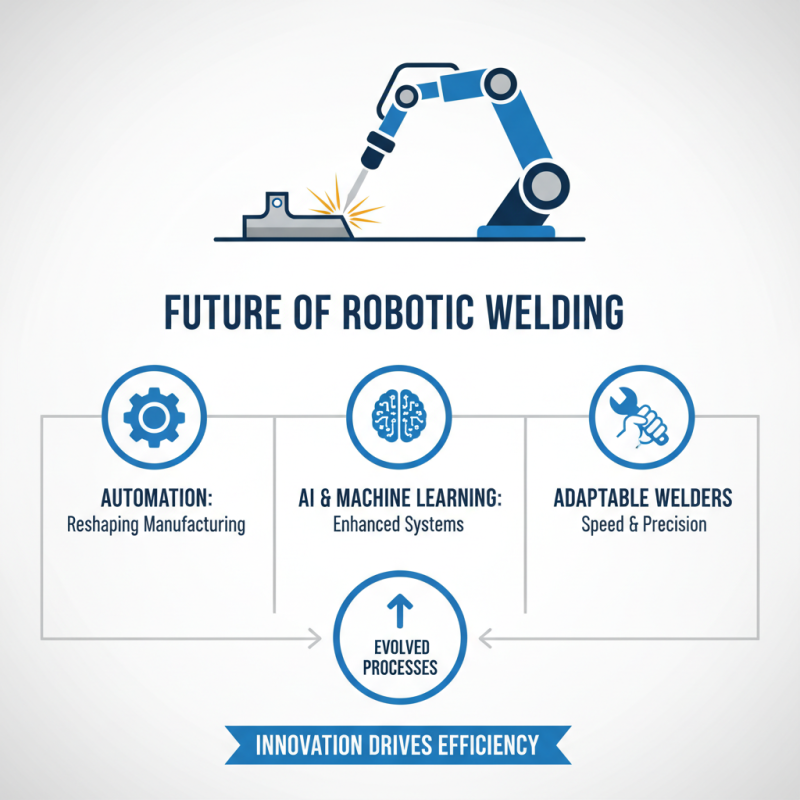

The future of robotic welding is evolving rapidly. Automation is reshaping manufacturing processes. Innovations in AI and machine learning are enhancing these systems. Welders can learn and adapt to different tasks efficiently. This adaptability improves speed and precision.

One significant trend is the integration of real-time data analytics. Robots can now assess their performance during operations. They provide feedback that can improve processes significantly. However, not all systems are perfect. Sometimes they struggle with complex geometries. This creates opportunities for further improvement and design iteration.

Customization is becoming more prevalent. Manufacturers seek tailored solutions for specific projects. However, balancing customization with efficiency proves challenging. It leads to potential delays in production. Organizations need to reflect on these issues. As the industry progresses, understanding these limitations will be crucial for success.