Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

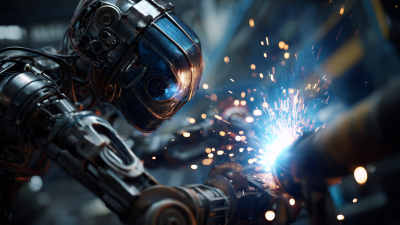

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

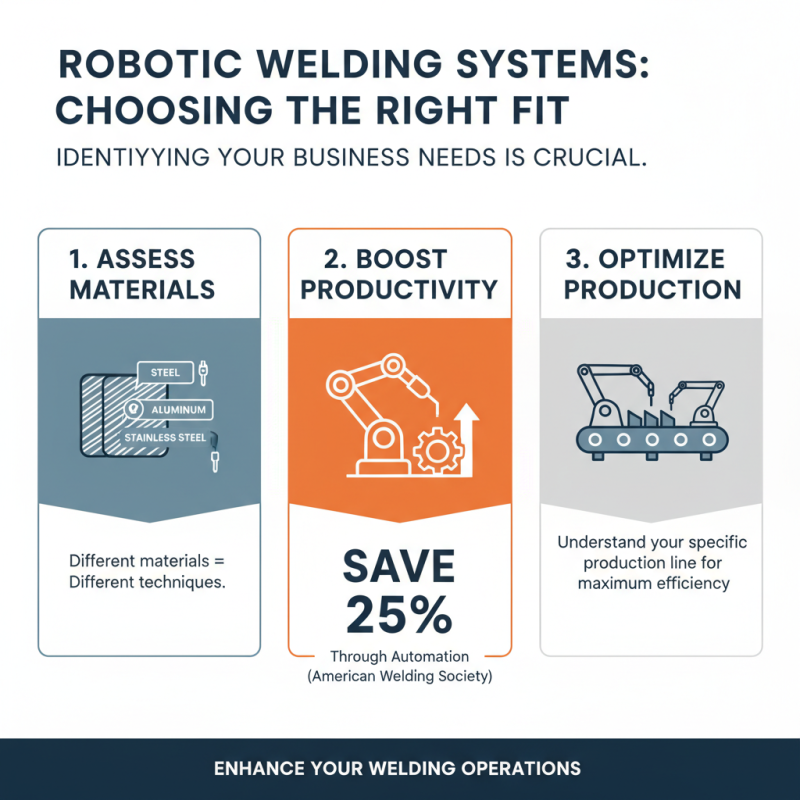

In the evolving landscape of manufacturing, choosing the right robotic welding systems is crucial for businesses aiming to stay competitive. Industry expert Dr. Emily Carter notes, "Selecting the right robotic welding solution can significantly enhance productivity and reduce errors." This underscores the importance of a well-inform decision-making process.

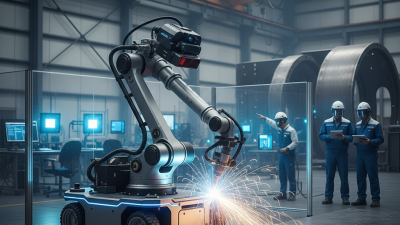

When considering robotic welding systems, businesses must assess their specific needs. Factors such as material types, production volume, and welding techniques play significant roles. A mismatch can lead to inefficiencies. For instance, a company focusing on high-volume production may require a different system than one tackling custom projects.

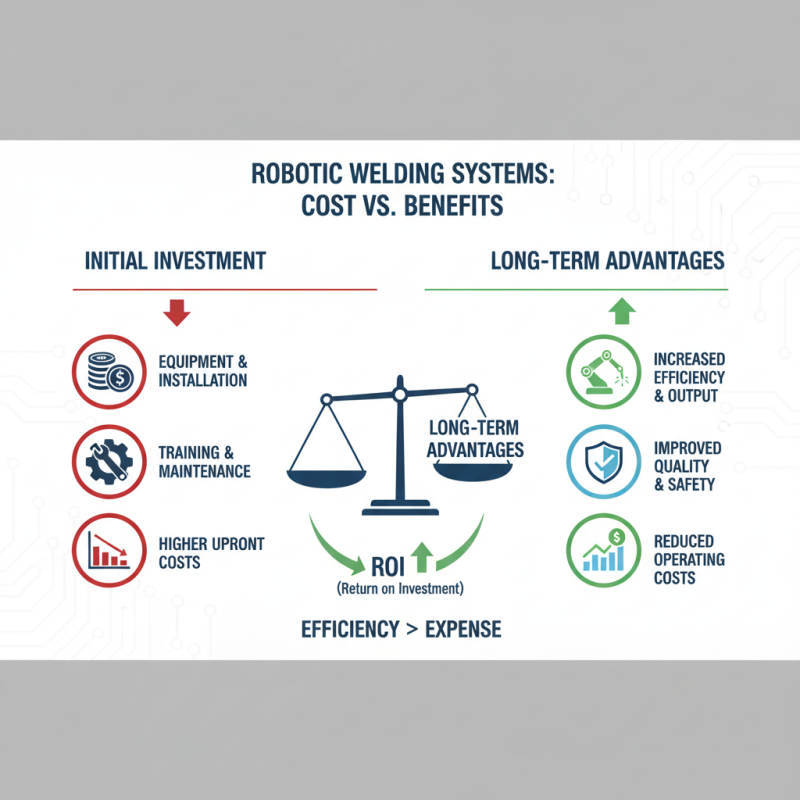

Moreover, it’s essential to keep in mind the costs involved. While investing in advanced robotic welding systems may seem daunting, the long-term benefits often outweigh the initial expenditure. Operating too hastily can lead to regret. Therefore, weighing all aspects carefully is vital for achieving optimal outcomes in a business’s welding capabilities.

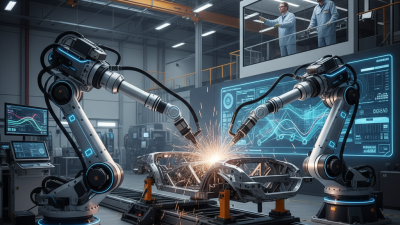

Robotic welding systems have transformed the manufacturing landscape. They deliver speed and precision that manual welding cannot match. Understanding the basics of these systems is essential for making informed decisions. At their core, robotic welders use advanced technology to automate welding processes. They can handle various materials, such as steel, aluminum, and more.

Choosing the right system requires careful thought. Consider your production volume and welding requirements. A system that works for one business might not suit another. Pay attention to the type of welding required, like MIG or TIG. Each method presents its benefits and drawbacks. Reflect on how much training your staff will need. Not everyone can operate robotic equipment with ease.

Additionally, think about the size and layout of your workspace. Some robotic systems need significant floor space. It’s also crucial to assess ongoing maintenance costs. Neglecting this can lead to unexpected downtime. Every detail matters when selecting a robotic welding system. A hasty choice can result in inefficiencies and frustrations.

Identifying your business needs is crucial when choosing robotic welding systems. Begin by assessing the materials you typically work with. Steel, aluminum, or stainless steel all require different welding techniques. The American Welding Society states that organizations can enhance productivity by 25% through automation. Yet, understanding the specifics of your production line is essential for this to occur.

Consider your production volume as well. High-volume jobs may benefit from a fully automated solution. In contrast, variable production needs might require a more flexible system. Data from the International Federation of Robotics shows that 34% of manufacturers still rely on manual methods. Adapting might seem daunting, but the ROI can be significant if aligned with your objectives.

Tips: Keep an eye on the scalability of the system. Will it grow with your business? Investigate how training is provided for staff. Many advanced systems require new skills, which could be a barrier. Do not overlook maintenance costs. They can impact long-term profitability. Reflect on these aspects carefully to ensure a fit for your business.

When choosing robotic welding technologies, it's essential to understand the various options available. Different systems come with unique features suited for specific tasks. For example, arc welding robots are common in automotive industries. They offer precision and can handle various materials effectively.

Laser welding systems are also gaining popularity. They are fast and can achieve high-quality welds with minimal distortion.

Another technology to consider is spot welding. This method is typically used in mass production. It's efficient and can help reduce cycle times. However, it may not be ideal for complex geometric shapes. Each technology has its strengths and weaknesses. Business owners must carefully evaluate their needs and production goals.

It’s important to assess the learning curve involved with each system. Some may require extensive training for operators. This can increase initial costs and delay productivity. Additionally, compatibility with existing equipment is vital. Integrating new systems can pose challenges and needs thoughtful planning. Balancing these factors is critical in making a wise investment.

When considering robotic welding systems, analyzing cost versus benefits is crucial. Initial investments can seem daunting. However, their long-term advantages often outweigh these expenses. A new system may require training and maintenance, adding to upfront costs. Yet, efficiency gains can significantly boost production rates.

Labor costs can also factor into the equation. Robots can handle repetitive tasks, freeing human workers for more complex roles. This transition may lead to resistance from the workforce. It's essential to address these concerns thoughtfully. The integration process should be transparent and supportive.

Moreover, quality improvement is a significant benefit. Robotic welding systems consistently produce high-quality products. This reduces waste and rework rates. However, if not programmed correctly, these systems can create defects. Continuous evaluation and adjustments are necessary. Balancing cost and benefits demands careful planning and strategic decisions.

When selecting robotic welding systems, finding a reliable supplier is crucial. A dependable supplier provides quality products and support. Look for suppliers with a solid reputation and positive feedback from clients. Check how long they have been in the industry. Experience often suggests stability and expertise. Research their after-sales support and service offerings too.

Tips: Ask for testimonials from previous clients. This can help gauge reliability.

Another important factor is technical support. You want a supplier who is responsive. In case of issues, timely support minimizes downtime. Ensure they offer training for your staff as well. This investment can help maximize the efficiency of your robotic systems. Regular maintenance services are also essential. If you neglect this, performance can suffer.

Tips: Evaluate the supplier's commitment to your success. Their long-term support can make a big difference. Good communication is key. Don't overlook the importance of a solid partnership in this industry.

| Criteria | Description | Importance Level | Supplier Support |

|---|---|---|---|

| Robotic Technology | Type of robotic welding technology (MIG, TIG, etc.) | High | Technical training availability |

| Customization Options | Ability to tailor systems to specific needs | Medium | Flexible service offerings |

| Automation Level | Integration with existing automation solutions | High | Comprehensive support during implementation |

| Cost of Ownership | Initial purchase cost and long-term maintenance | High | Warranty and parts availability |

| Reliability and Performance | Track record of the equipment in various applications | High | Response time for support requests |

| Training and Documentation | Availability of user manuals and training programs | Medium | Online resources and updates |