Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

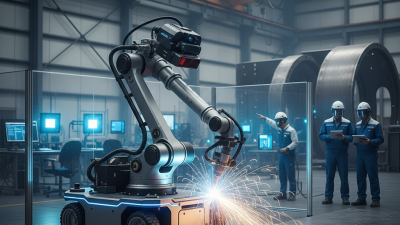

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

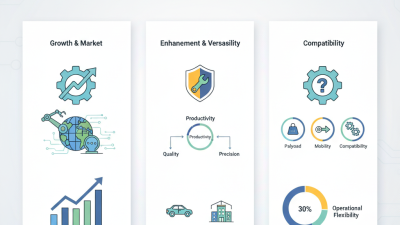

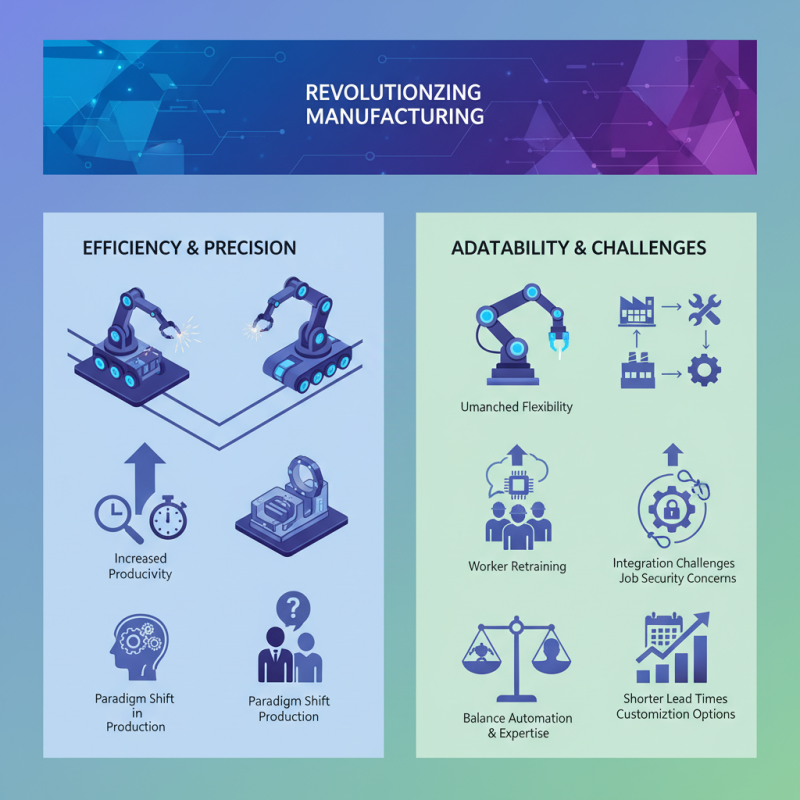

The manufacturing industry is undergoing a significant transformation with the advent of mobile welding robots. These innovative machines enhance efficiency and precision in welding tasks. Expert in robotics, Dr. Emily Chen, states, “Mobile welding robots are not just tools; they are changing how we think about production.” This paradigm shift impacts job roles and work processes.

Mobile welding robots offer unmatched flexibility. They can seamlessly move between workstations, adapting to various tasks. However, the integration of these robots comes with challenges. Workers need to retrain and adjust to new technologies. The transition may not always be smooth, raising concerns about job security. Manufacturers must balance automation with human expertise.

Yet, the benefits are hard to overlook. Companies adopting mobile welding robots report increased productivity and shorter lead times. With customization options, these robots cater to specific needs. The future of manufacturing is bright, but it requires careful navigation through this technological evolution.

Mobile welding robots are transforming the manufacturing landscape. Advances in technology are making these devices more efficient and versatile. They can now operate in various environments, adapting to different types of materials. Improved sensors and AI integration allow for precise welding, even in tight spaces.

These robots are designed to be user-friendly. Operators require less training than before. Yet, there are challenges. Some robots can struggle with complex geometries. Adjusting settings for different jobs can be time-consuming. Despite improvements, there is still room for growth in usability and flexibility.

The mobility of these robots is a game changer. They can move between workstations, reducing downtime. Smaller companies benefit from these cost-effective solutions. However, not every facility is ready to adopt this technology. Infrastructure needs to be updated. As mobile welding robots continue to evolve, the industry must address these hurdles.

Mobile welding robots are transforming manufacturing with their versatility and efficiency. These machines can operate in various environments, adapting to different welding processes seamlessly. They free up human workers from repetitive tasks, allowing them to focus on higher-level responsibilities like quality control. This leads to increased productivity on the shop floor.

One significant benefit is precision. Mobile welding robots execute welds with utmost accuracy, reducing error rates. A slight misalignment can lead to costly rework, but these machines excel in maintaining consistency. With the ability to collect data, manufacturers can analyze performance and improve their processes. However, there is an initial learning curve for operators. They may require training to manage these advanced systems effectively.

Another key aspect is cost savings. While the upfront investment in technology can be high, the long-term savings are compelling. Reducing labor costs and minimizing material waste can have a significant impact on a company's bottom line. Still, some companies hesitate, fearing potential technical issues. Integrating these robots may sometimes challenge existing workflows, but the long-term benefits are hard to ignore.

Mobile welding robots are making waves in the manufacturing sector. Their impact on production efficiency is notable. These robots can work continuously, reducing downtime significantly. Operations that once took hours now take minutes. This acceleration boosts overall output.

Cost reduction is another critical benefit. By using mobile welding robots, manufacturers lower labor costs. Fewer workers are needed onsite, which reduces recruitment and training expenses. Additionally, these robots can minimize material waste. Precision welding leads to cleaner cuts and joins, cutting excess raw material usage.

However, the transition isn't flawless. Some workers may fear job displacement. There is also a learning curve associated with adapting to robotic technology. Maintenance and repairs can be costly, too. Balancing automation with human skills is essential for long-term success. Manufacturing leaders must navigate these challenges carefully.

Mobile welding robots have transformed the manufacturing landscape. However, there are notable challenges and limitations that companies face. One major issue is mobility itself. While these robots can move around, their performance is often hindered by uneven surfaces and obstacles. This can lead to inconsistent welding quality, requiring manual adjustments.

Another challenge is programming complexity. Operators need specialized training to handle these advanced machines. Room for error exists, as improper programming can cause significant delays and defects. Additionally, the robots may struggle with intricate designs. Some tasks still require human intervention for optimal results.

The reliance on technology can also lead to vulnerabilities. If several robots malfunction simultaneously, production can come to a standstill.

Cost is another factor to consider. Initial investments are high, and maintenance can be burdensome. For small or medium-sized manufacturers, this can be a barrier. Moreover, software updates may require additional expense and expertise. All these limitations necessitate thoughtful reflection and a strategic approach to integrating mobile welding robots into existing workflows.

Mobile welding robots are gaining traction in the manufacturing sector. They offer flexibility and efficiency. These compact robots can easily navigate tight spaces and perform intricate jobs. This capability allows them to work in various environments, from factories to construction sites.

Future trends suggest that mobile welding robotics will become more advanced. Integration with AI and machine learning is likely. These advancements could enhance precision and reduce errors. Manufacturers may also adopt more user-friendly interfaces, making these robots accessible to non-experts. However, challenges remain. Training workers to collaborate with these machines can be difficult. Ensuring safety in shared environments is also a concern.

Moreover, the cost of initial investment can be a barrier for some businesses. It's crucial to consider long-term benefits versus upfront costs. As technology evolves, so will the strategies for implementation. This evolution will certainly influence the industry's future trajectory.