Lincoln Electric ® acquires Inrotech A/S

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Vision-Based Adaptive Intelligence Software Extends Lincoln Electric’s Technology Platform -Lincoln Electric® is pleased to announce that it has acquired Inrotech A/S. Headquartered in Odense, Denmark,

Inrotech has received an order from Tersan Shipyard, a diversified company with expertise in constructing LNG and battery-operated vessels, as well as various value-added niche

Inrotech welcomes Henrik Lenskjold as its new Chief Executive Officer. Henrik, who served as the Chief Operation Officer at Inrotech for six years, has been

Welding robots originating from Denmark have gained substantial popularity within the Turkish shipbuilding industry for the welding of ship panels. Ada Shipyard, a prominent shipyard

Inrotech has received an order from Santierul Naval Orsova Shipyard, a leading shipbuilder in Romania. The company invest in high quality welding automation as a

The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience

In the rapidly evolving field of welding robot programming, staying ahead of trends is crucial. Industry expert Dr. Emily Carter, a leading figure in automation technology, emphasizes, "The future of welding lies in our ability to adapt and innovate." As 2026 approaches, several key trends will shape the landscape of welding automation.

Welding robot programming is becoming more sophisticated. The integration of artificial intelligence and machine learning is revolutionizing the way robots operate. These advancements enhance precision and efficiency. Additionally, there is a growing focus on user-friendly programming interfaces. This shift caters to a wider range of operators, from beginners to seasoned professionals.

However, challenges remain. Many companies struggle to implement these technologies effectively. There is a notable gap in training and education. Addressing this is vital for the industry's growth. As we explore these trends, we must reflect on our readiness to embrace them. The future of welding could hinge on our response to these changes. It's a turning point worth watching closely.

As we look towards 2026, several emerging technologies will shape the landscape of welding robot programming. Artificial intelligence (AI) will play a critical role. AI can analyze data in real-time to optimize welding processes. This technology will enhance accuracy and efficiency. Robots may learn from previous tasks, improving continuously over time.

Incorporating machine learning could also transform welding automation. Machines may predict issues before they arise. This proactive approach minimizes downtime. However, relying heavily on these technologies may lead to unexpected challenges. Operators must remain vigilant and ready to troubleshoot malfunctions.

Tips: Regular training for operators is essential. Stay updated on technological advancements. A well-informed workforce can leverage these innovations effectively. Additionally, testing new programming methods in small batches helps identify potential pitfalls. Embracing change is vital, but so is careful implementation. Balancing innovation with practical experience will be key to success.

This chart displays the anticipated trends in welding robot programming for 2026. The data includes the expected growth in adoption rates for various emerging technologies in the field.

The rise of AI and machine learning is transforming welding automation. These technologies enhance the accuracy of welding processes. They can reduce errors and improve weld quality. Skilled human oversight is still required, however. Mistakes will happen, and robots are not infallible.

Adopting AI in welding requires a shift in mindset. Operators need to learn new skills. They must understand both the technology and welding principles. Training programs should focus on this dual aspect. Emphasizing adaptability will help teams adjust.

**Tip:** Integrate AI tools gradually. Start small and build confidence in the technology.

Collecting data is crucial for refining processes. Evaluating machine output helps identify common errors. Continuous feedback loops are essential.

**Tip:** Encourage team members to share insights. Open communication fosters improvement.

AI and machine learning hold great promise for welding. Yet, human experience is invaluable. Mistakes will highlight gaps in programming and training, prompting necessary adjustments. Embrace the journey, while understanding the nature of progress.

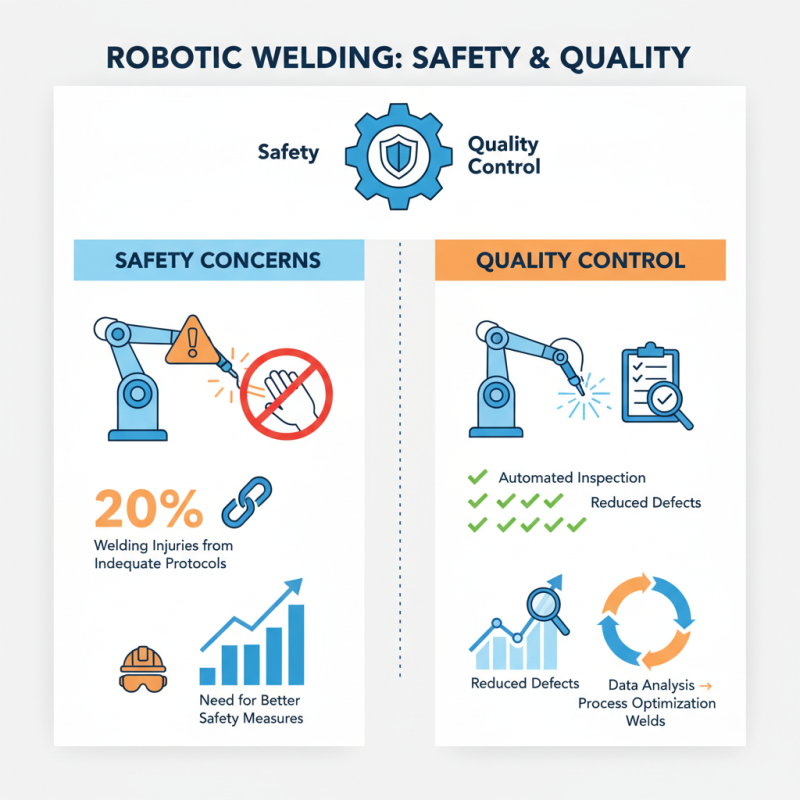

In the field of robotic welding, safety and quality control remain paramount concerns. Recent data reveals that improper handling of equipment leads to accidents. In fact, reports suggest that nearly 20% of welding injuries stem from inadequate safety protocols. This underscores the need for better safety measures in robotic welding increasingly.

Modern welding robots are now equipped with advanced sensors and machine learning algorithms. These technologies enhance quality control by detecting defects in real-time. According to industry insights, quality failures can cost manufacturers up to 5% of their revenue. Adopting robotic systems can reduce these losses significantly. However, there are questions about the effectiveness of current training programs for operators, who may not fully understand robotic systems' nuances.

Furthermore, while automation promises safety improvements, it brings challenges. User error can create risks if operators overlook critical safety features. A focus on continued education and proper training is essential to mitigate these gaps. Investing in safety-focused programming will benefit workers and increase overall productivity in welding operations.

The integration of IoT in welding robot programming is transforming the industry. As per recent reports, manufacturers can enhance productivity by 30% through effective IoT implementation. Real-time data collection is key. Sensors connected to welding robots monitor performance, identifying potential issues before they escalate. This leads to reduced downtime and improved overall efficiency.

Tip: Ensure all sensors are properly calibrated. Inaccurate data can lead to more mistakes and wasted resources. Further, IoT enables remote monitoring. Operators can check welding processes from anywhere. This flexibility allows for quicker adjustments and immediate problem-solving.

While IoT offers great advantages, challenges exist. Cybersecurity risks are a significant concern. Many companies are unprepared for potential attacks. Regular assessments and updates are essential to safeguard systems. Consider backups and fail-safes during implementation. Balancing innovation with security is crucial. The future of welding robots relies on thoughtful adaptation of these technologies.

| Trend | Description | Impact Level | Projected Adoption Rate (%) |

|---|---|---|---|

| Increased IoT Integration | Utilizing IoT devices to monitor and adjust welding robots in real-time. | High | 75 |

| AI-Driven Analytics | Leveraging AI to enhance decision-making and process optimization in welding. | Medium | 60 |

| Remote Monitoring | Enabling operators to monitor welding processes from remote locations. | High | 68 |

| Collaborative Robots (Cobots) | Robots designed to work alongside human operators to improve efficiency. | Medium | 65 |

| Enhanced Safety Features | Integrating smart sensors to detect hazards and improve workplace safety. | High | 70 |

As industries continue to evolve, advanced welding programming techniques emerge as essential for cost reduction. Automation in welding has the potential to minimize labor costs significantly. However, the initial investment can be daunting. Many businesses hesitate, unsure if the long-term savings will justify the upfront expenses. It’s a valid concern that deserves attention.

Efficient programming can enhance precision and reduce material waste. Fine-tuning welding parameters leads to better results but requires skilled operators. Each adjustment influences the overall outcome, which might not always align with expectations. Sometimes, trial and error is needed. This can result in increased downtime, which can be frustrating. Yet, the benefits of improved quality and speed often outweigh the initial setbacks.

Embracing new technologies in welding programming opens doors to innovative cost-saving strategies. However, companies must adapt to the learning curve that accompanies new systems. Regularly assessing these strategies helps ensure they remain relevant and effective. Engaging in ongoing education is crucial. Recognizing the gaps in current practices can inspire continuous improvement, ultimately leading to more sustainable operations.